Need a slope containment solution? NUOKUNgeo textured HDPE geomembrane offers superior interface friction. Designed for landfill slopes, tailings dams, and steep embankments. ASTM compliant, chemical resistant, >50-year service life. Request specs.

Color :

Black (regular), White, Green, BlueWeight :

1-8mThickness :

0.1-3.0mmLead Time :

7 -14 days after deposit paymentOrder(MOQ) :

2000㎡Payment :

FOB (Can communicate and negotiate)Product Origin :

ChinaShipping Port :

Qingdao

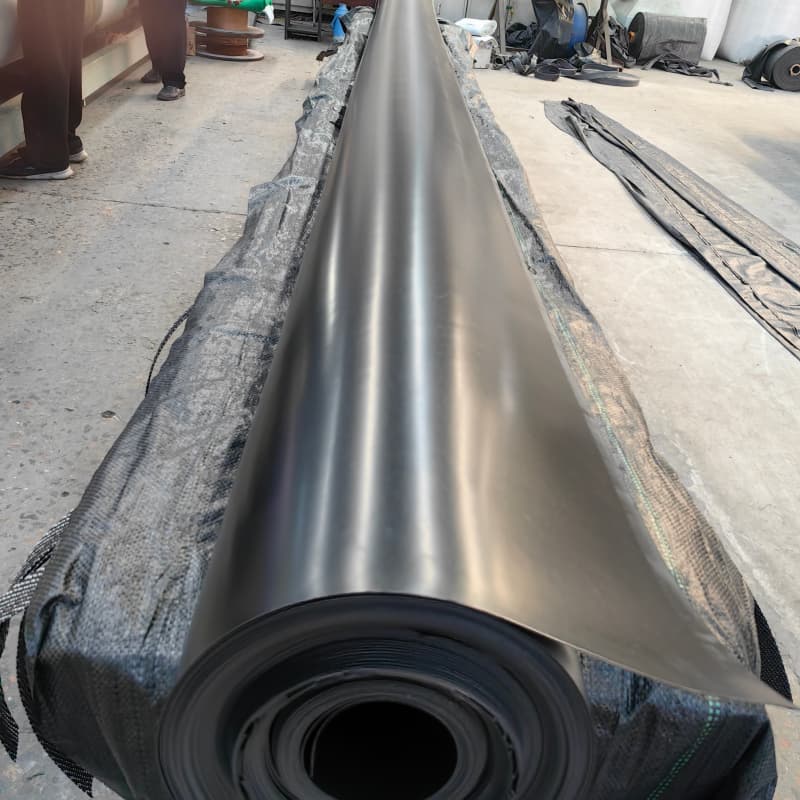

Engineering-Grade Textured HDPE Geomembrane: Designed for Demanding Slopes & Critical Containment Projects

When your project faces slope challenges of 1:2 or steeper, the friction coefficient of ordinary smooth geomembranes is insufficient to prevent the entire liner system from sliding. NUOKUNgeo textured (also known as structured surface) HDPE geomembrane, through a unique surface embossing process, increases its interface friction angle with geotextiles, sand, or clay to over 30 degrees. In long-term shear tests simulating 50 years of loading, our textured geomembrane-geotextile composite interface exhibits extremely low creep displacement of less than 1 mm/year, providing crucial long-term stability for mine heap leach pads, dams, and landfill slopes.

In-Depth Application Scenario Analysis

As the core impermeable layer in composite liner systems, its textured surface creates a powerful mechanical interlock with the underlying bentonite mat (GCL) or geotextile. This effectively prevents layer separation even under conditions of ongoing differential settlement, ensuring the integrity of the entire containment barrier.

Directly exposed to acidic or alkaline slag leachate with a pH range of 2-10. Our textured geomembrane not only provides high frictional stability but also exhibits Environmental Stress Crack Resistance (ESCR) exceeding 1500 hours (ASTM D5397), far above the standard requirement of 300 hours, enabling it to resist the dual attack of chemicals and stress.

In hydraulic engineering, laid on riverbank slopes to prevent water erosion. Its rough surface aids in the stable attachment of overlying protective layers (such as gabions or concrete slabs), reducing the risk of direct scouring by water flow on the liner.

"One-Side Textured" vs. "Two-Side Textured": A Precision Selection Guide

| Feature | One-Side Textured HDPE Geomembrane | Two-Side Textured HDPE Geomembrane |

|

Structure

|

One side smooth, one side rough. | Both sides have a rough texture. |

|

Primary Purpose

|

Slope anti-slip and subgrade fixation.The smooth side faces up for easier weld inspection and overlying material placement. |

"Sandwich" structures requiring high friction with both upper and lower layers. |

| Typical Applications |

Landfill slopes (textured side down contacting GCL), upstream slopes of earth dams. |

Steep heap leach pads (geotextile on both sides), intermediate layer in double liner systems, very steep rock slopes. |

| Welding Convenience |

Smooth-to-smooth welding, same as standard smooth geomembrane, easy quality control. |

Textured-to-textured welding requires specialized procedures, but NUOKUNgeo provides matching welding parameter guidance. |

| Cost-Effectiveness |

More economical in scenarios requiring friction on only one side. |

Provides a comprehensive solution for the most demanding stability requirements. |

Key Q&As About Textured Geomembranes

Q1: What is the specific friction coefficient of textured geomembrane? How is it tested?

A1:The interface friction angle (Φ)of our product varies depending on the paired material. For example, it can reach 28-32 degrees when paired with non-woven geotextile, and 25-28 degrees with fine sand. Testing strictly follows the ASTM D5321 standard for "Direct Shear Testing." We can provide test reports issued by authoritative laboratories.

Q2: How is the thickness of textured geomembrane measured? Does it include the rough surface?

A2:This is an important distinction! The nominal thickness specified by international standards (such as ASTM) refers to the base material thickness, excluding the rough protrusions. For example, a textured geomembrane with a nominal thickness of 1.5mm has a base material thickness of 1.5mm in its flat sections, with protrusions adding an extra ~0.2-0.5mm. We ensure the base material thickness fully complies with standards—no cutting corners.

Q3: Is welding and leak detection more difficult with textured geomembranes?

A3:Yes, it requires more skill. Welding requires cleaning protruding particles from the weld area and using validated welding parameters. Leak detection (e.g., vacuum box method) requires more meticulous care to ensure a seal. NUOKUNgeo provides detailed Welding Procedure Specifications (WPS) for all textured geomembrane projects and strongly recommends welder training and sample testing.

Q4: Will textured geomembranes become brittle in cold regions?

A4:HDPE's toughness decreases at low temperatures. However, by selecting high-toughness resin formulations, our products maintain good performance even in low-temperature impact tests at -40°C. For projects in extremely cold regions, we recommend using our series of products specifically designed for low temperatures.

Q5: Can you provide on-site technical support for projects?

A5:Yes. For large or critical projects, NUOKUNgeo can dispatch experienced on-site technical representatives to provide guidance during the initial stages of laying and welding, ensuring construction norms comply with the design plan and safeguarding project quality from the source.

|

|

Packing And Delivery

|

|

|

|

|

|

|

|

FAQ

1、What guarantees do you get when you choose us?

Certification guarantee: CE/ISO 9001/GRI GT13 (17)

15-Day Lead Time: Direct supply from Shandong manufacturing base (FOB Qingdao Port)

Pre-production samples are always conducted before mass production;

Final inspection is always conducted before shipment;

If you have any questions about us and our products, please feel free to contact us.

2、Can we get some samples? Is there a charge?

Yes, we can provide samples for free, but we do not pay for the shipping.

If you place an order after confirming the sample, we will refund your shipping fee or deduct it from the order amount.

leave a message

Scan to Wechat/Whatsapp :